Fiberglass gel coat is a material that is commonly used in the manufacturing of boats, RVs, and other recreational vehicles. It is a protective layer that is applied to the surface of a fiberglass mold to provide a smooth and durable finish.

The gel coat is typically made from a mixture of polyester resin and pigments, which can be customized to match any color or texture.

One of the key benefits of fiberglass gel coat is its ability to protect the underlying fiberglass from damage caused by UV rays, moisture, and other environmental factors.

The gel coat acts as a barrier, preventing water from penetrating the fiberglass and causing it to weaken or delaminate. It also helps to prevent fading and discoloration, ensuring that the finished product looks great for years to come.

Overall, fiberglass gel coat is an essential component in the manufacturing of high-quality boats, RVs, and other recreational vehicles. Its ability to provide a protective layer that is both durable and aesthetically pleasing makes it an ideal choice for anyone looking to create a long-lasting and visually appealing product.

Understanding Fiberglass Gel Coat

Fiberglass gel coat is a protective layer applied to the surface of fiberglass reinforced plastic (FRP) materials. It is a resin-based material that is sprayed or brushed onto the surface of the FRP and then cured to form a hard, durable finish 2.

The primary purpose of fiberglass gel coat is to protect the underlying material from environmental factors such as UV rays, water, and abrasion. It also provides a smooth, glossy finish that is aesthetically pleasing.

Fiberglass gel coat is available in a variety of colors and can be customized to match the desired color scheme of a project. It is also possible to add pigments and other additives to the gel coat to enhance its properties.

One of the benefits of fiberglass gel coat is that it can be easily repaired if damaged. Small scratches and chips can be filled in with gel coat repair kits, restoring the surface to its original condition.

Overall, fiberglass gel coat is an important component in the construction of FRP materials. It provides protection and enhances the appearance of the finished product.

Components of Fiberglass Gel Coat

Fiberglass gel coat is a type of coating applied to the surface of fiberglass to provide a smooth, durable, and glossy finish. It is a mixture of polyester resin, pigments, and additives that are sprayed or brushed onto the surface of the fiberglass mold before the fiberglass is laid down.

Polyester Resin

Polyester resin is the primary component of fiberglass gel coat. It is a thermosetting plastic that is made by reacting a liquid unsaturated polyester resin with a catalyst and a hardening agent. The resulting resin has excellent adhesion to fiberglass and can be formulated to have a wide range of physical and mechanical properties.

Pigments

Pigments are added to the polyester resin to give the gel coat its color. They can be organic or inorganic and come in a wide range of colors. The pigments used in gel coat are specially formulated to resist fading and weathering, ensuring that the color of the gel coat remains vibrant and consistent over time.

Additives

Additives are used in gel coat to improve its performance and physical properties. These can include UV stabilizers to protect against sun damage, fire retardants to improve fire resistance, and thickeners to control viscosity.

In conclusion, fiberglass gel coat is a specialized coating that is used to provide a smooth, durable, and glossy finish to fiberglass. It is made up of polyester resin, pigments, and additives that are carefully formulated to provide the desired properties and performance.

Production Process

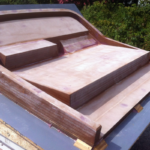

Preparation

Before the application of fiberglass gel coat, the surface to be coated must be cleaned and prepared. This involves removing any dirt, grease, and other contaminants that may prevent proper adhesion of the gel coat. The surface is then sanded to create a rough texture, which allows the gel coat to adhere better.

Application

The fiberglass gel coat is applied using a spray gun or a brush. The gel coat is usually applied in two or three layers, with each layer being allowed to dry before the next layer is applied. The thickness of the gel coat depends on the application and the desired finish. A thicker gel coat provides better protection against UV rays and abrasion.

Curing

After the gel coat is applied, it must be allowed to cure. The curing process involves the chemical reaction between the gel coat and the catalyst.

The time required for curing depends on the temperature, humidity, and the thickness of the gel coat. Typically, the gel coat is allowed to cure for 24 to 48 hours before the surface can be sanded or polished.

Overall, the production process of fiberglass gel coat involves preparation, application, and curing. The proper execution of each step is crucial for achieving a high-quality finish.

Properties of Fiberglass Gel Coat

Durability

Fiberglass gel coat is known for its durability and resistance to wear and tear. It is a highly durable material that can withstand harsh environmental conditions, including exposure to UV rays, water, and chemicals.

The gel coat is applied to the surface of the fiberglass material, creating a protective layer that helps to prevent damage to the underlying material. This makes it an ideal choice for use in marine applications, where exposure to saltwater and other harsh conditions is common.

Appearance

Fiberglass gel coat is also known for its attractive appearance. It is available in a wide range of colors and finishes, allowing for customization to suit any design preference. The gel coat can be polished to a high gloss finish, giving it a sleek and shiny appearance. It can also be textured to create a more matte finish, which is ideal for applications where a non-slip surface is required.

Maintenance

Fiberglass gel coat is relatively low maintenance, making it an ideal choice for applications where regular upkeep is not feasible.

It is resistant to fading and discoloration, which means that it will maintain its appearance over time. The gel coat can be cleaned using mild soap and water, and it is also resistant to stains and scratches.

Overall, fiberglass gel coat is a versatile and durable material that offers a range of benefits for a variety of applications. Its durability, attractive appearance, and low maintenance requirements make it an ideal choice for use in marine, automotive, and other industries.

Applications of Fiberglass Gel Coat

Fiberglass gel coat is a versatile material that finds wide application in various industries. Here are some of the most common applications of fiberglass gel coat:

Marine Industry

Fiberglass gel coat is widely used in the marine industry due to its excellent resistance to water, weathering, and UV rays.

It is used to coat the exterior of boats, yachts, and other watercraft to protect them from the harsh marine environment. Fiberglass gel coat is also used to manufacture marine accessories such as seats, hatches, and covers.

Automotive Industry

Fiberglass gel coat is also used in the automotive industry to manufacture car bodies, spoilers, and other exterior parts.

Its excellent resistance to weathering, impact, and corrosion makes it an ideal material for automotive applications. Fiberglass gel coat is also used in the manufacture of aftermarket car parts and accessories.

Construction Industry

Fiberglass gel coat is widely used in the construction industry to manufacture various building components such as panels, doors, and windows.

Its excellent resistance to weathering, impact, and corrosion makes it an ideal material for exterior applications. Fiberglass gel coat is also used to manufacture decorative elements such as columns, cornices, and moldings.

In conclusion, fiberglass gel coat is a versatile material that finds wide application in various industries. Its excellent resistance to weathering, impact, and corrosion makes it an ideal material for exterior applications.

Advantages and Disadvantages

Pros of Fiberglass Gel Coat

Fiberglass gel coat has several advantages that make it a popular choice for boat builders and manufacturers. One of the main benefits of fiberglass gel coat is its durability. It can withstand harsh weather conditions, UV rays, and saltwater, making it an ideal material for boats and marine applications.

Another advantage of fiberglass gel coat is its ability to resist scratches and abrasions. This is due to the high-quality resins and additives used in its production. Additionally, fiberglass gel coat is easy to clean and maintain, which is important for boat owners who want to keep their vessels looking their best.

Fiberglass gel coat is also available in a wide range of colors and finishes, making it a versatile material for design and customization. It can be molded into various shapes and sizes, allowing for intricate designs and complex structures.

Cons of Fiberglass Gel Coat

While fiberglass gel coat has many advantages, it also has some disadvantages that should be considered. One of the main drawbacks of fiberglass gel coat is its susceptibility to cracking and chipping. This can occur due to impact or stress, and it can be difficult to repair.

Another disadvantage of fiberglass gel coat is its tendency to fade over time. This is especially true for boats that are exposed to sunlight and saltwater on a regular basis. While regular maintenance can help to slow down the fading process, it is still a concern for some boat owners.

Lastly, fiberglass gel coat is not as environmentally friendly as some other materials. The production process can be energy-intensive, and the material itself is not biodegradable. However, some manufacturers are working to develop more sustainable alternatives to traditional fiberglass gel coat.

Overall, fiberglass gel coat is a popular and widely used material for boats and other marine applications. Its durability, versatility, and ease of maintenance make it a top choice for many boat builders and owners.

However, it is important to consider the potential drawbacks before making a decision about using fiberglass gel coat.

Conclusion

Fiberglass gel coat is a protective layer applied to fiberglass surfaces to enhance their durability and appearance. It is a popular choice for boats, automobiles, and other applications where a glossy, smooth finish is desired.

Overall, fiberglass gel coat is a reliable and effective solution for protecting fiberglass surfaces from damage caused by UV radiation, water exposure, and other environmental factors. It is also resistant to scratches and impacts, making it a great choice for high-traffic areas.

When applying fiberglass gel coat, it is important to follow the manufacturer’s instructions carefully to ensure proper adhesion and curing. Additionally, regular maintenance and cleaning can help prolong the lifespan of the gel coat and keep the surface looking its best.

In conclusion, fiberglass gel coat is a versatile and durable solution for protecting and enhancing the appearance of fiberglass surfaces. Whether you’re working on a boat, car, or other fiberglass application, investing in a high-quality gel coat can help ensure long-lasting protection and a beautiful finish.