Fiberglass and aluminum are two popular materials used in many industries, including construction, aviation, and transportation. Both materials have unique properties that make them suitable for various applications.

One of the most common questions and debates among professionals is “Is Fiberglass Lighter Than Aluminum”. In this article, we will explore this topic and provide a clear answer.

Fiberglass is a composite material made of glass fibers and resin. It is a popular choice in the construction industry due to its durability, strength, and resistance to corrosion.

On the other hand, aluminum is a lightweight metal that is commonly used in the aviation industry due to its strength-to-weight ratio. While both materials have their advantages, the question remains: which is lighter?

To answer this question, we need to compare the weight of fiberglass and aluminum. However, it’s important to note that the weight can vary depending on the specific type and thickness of the material used.

In the next section, we will compare the weight of fiberglass and aluminum in various applications to determine which is lighter.

Understanding Fiberglass

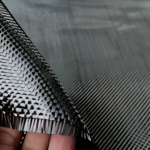

Composition

Fiberglass is a composite material made of glass fibers and resin. Glass fibers are made by drawing molten glass into thin strands. These strands are then woven together to create a fabric-like material. The fibers are then coated with a resin, usually polyester or epoxy, which hardens to create a strong and durable material.

Properties and Uses

Fiberglass is known for its strength and durability. It is also lightweight, making it a popular choice for applications where weight is a concern. Fiberglass is commonly used in the construction of boats, aircraft, and automobiles, as well as in the manufacturing of sports equipment such as golf clubs and fishing rods.

In terms of weight, fiberglass is generally lighter than aluminum. However, the exact weight of a fiberglass material will depend on the specific type of resin and glass fibers used. It is important to note that while fiberglass is lighter than aluminum, it may not be as strong in certain applications.

Overall, fiberglass is a versatile and durable material that is widely used in various industries. Its lightweight properties make it a popular choice for applications where weight is a concern, but it is important to consider the specific requirements of each application when choosing between fiberglass and other materials 5.

Understanding Aluminum

Composition

Aluminum is a chemical element with the symbol Al and atomic number 13. It is a silvery-white, soft, non-magnetic, ductile metal in the boron group. Aluminum is the third most abundant element in the Earth’s crust, after oxygen and silicon. It makes up about 8% by weight of the Earth’s solid surface.

Aluminum is produced from bauxite, a mineral found mostly in tropical areas. The process of extracting aluminum from bauxite involves refining it into alumina and then smelting it in a furnace with carbon electrodes. The resulting liquid metal is then cast into various shapes, including sheets, plates, and extrusions.

Properties and Uses

Aluminum has several desirable properties that make it a popular material for a wide range of applications. One of its most notable properties is its low density, which makes it lightweight and easy to handle. It has a density of 2.7 g/cm³, which is about one-third the density of steel.

In addition to its low density, aluminum is also corrosion-resistant, non-magnetic, and has good thermal and electrical conductivity.

These properties make it an ideal material for use in the construction of aircraft, automobiles, and other transportation vehicles, as well as in the production of cans, foil, and other packaging materials.

Overall, aluminum is a versatile and widely used material that offers a range of benefits for various applications.

Comparing Weight: Fiberglass Vs Aluminum

When it comes to choosing between fiberglass and aluminum, one of the most important factors to consider is weight. Both materials have their pros and cons, but weight can be a critical factor depending on the application.

Fiberglass is a composite material made of glass fibers and resin. It is known for being lightweight, yet strong and durable. On the other hand, aluminum is a metal that is also lightweight but known for its strength and corrosion resistance.

In terms of weight, fiberglass is generally lighter than aluminum. For example, a 14-foot fiberglass boat can weigh as little as 200 pounds, while a comparable aluminum boat may weigh 300 pounds or more. This weight difference can make a significant impact on fuel efficiency and overall performance.

However, it’s important to note that the weight of fiberglass and aluminum can vary depending on the specific application and design. For example, an aluminum boat with a thinner hull may be lighter than a fiberglass boat with a thicker hull.

Overall, when comparing weight between fiberglass and aluminum, fiberglass tends to be lighter. However, it’s important to consider other factors such as strength, durability, and cost when making a decision between the two materials.

Factors Influencing Weight

When comparing the weight of fiberglass and aluminum, there are several factors that come into play. Here are some of the key factors that influence the weight of these materials:

Density

Density is the mass of a material per unit volume. Fiberglass has a lower density than aluminum, which means that a given volume of fiberglass will weigh less than the same volume of aluminum.

Thickness

The thickness of a material also plays a role in its weight. Fiberglass can be made thinner than aluminum while still maintaining the same strength, which means that fiberglass can be lighter than aluminum in certain applications.

Alloy Composition

Aluminum alloys can vary in their composition, which can affect their weight. Some aluminum alloys are lighter than others, so it’s important to consider the specific alloy being used when comparing the weight of fiberglass and aluminum.

Design

The design of a structure or component can also impact its weight. Fiberglass can be molded into complex shapes, which can reduce the need for additional support structures and ultimately result in a lighter weight.

On the other hand, aluminum can be machined into precise shapes, which can reduce waste and result in a lighter weight.

Overall, the weight of fiberglass and aluminum depends on a variety of factors. While fiberglass may be lighter than aluminum in some applications, it’s important to consider the specific requirements of each application when choosing a material.

Practical Applications of Fiberglass and Aluminum

Fiberglass and aluminum are materials that are commonly used in various industries due to their unique properties.

While aluminum is a lightweight and durable metal, fiberglass is a strong and lightweight composite material that is made up of glass fibers and resin. Both materials have their own advantages and disadvantages, and their practical applications depend on the specific needs of the industry.

Fiberglass

Fiberglass is a popular material in the construction industry due to its strength, durability, and lightweight nature. It is often used to make boats, aircraft, automotive parts, and even building structures. Fiberglass is also a good insulator and can be used to insulate homes and buildings, as well as pipes and tanks.

One of the advantages of fiberglass is that it is resistant to corrosion and can withstand exposure to harsh weather conditions. It is also a good electrical insulator and does not conduct electricity, which makes it a safe material to use in electrical applications.

Aluminum

Aluminum is a lightweight and strong metal that is commonly used in the aerospace, automotive, and construction industries.

It is also a good conductor of heat and electricity, which makes it a popular choice for electrical applications. Aluminum is also resistant to corrosion and can withstand exposure to harsh weather conditions.

One of the advantages of aluminum is that it is easy to work with and can be easily formed into different shapes and sizes. It is also a recyclable material, which makes it an environmentally friendly option for various industries.

In conclusion, both fiberglass and aluminum have their own practical applications in various industries. While fiberglass is a strong and lightweight material that is resistant to corrosion and a good insulator, aluminum is a lightweight and durable metal that is easy to work with and a good conductor of heat and electricity.

The choice between these materials depends on the specific needs of the industry and the application at hand.

Advantages and Disadvantages

Fiberglass and aluminum are two popular materials used in various industries, including construction, transportation, and aerospace. While both materials have their advantages and disadvantages, it’s essential to understand the differences between them to make an informed decision.

Advantages of Fiberglass

Fiberglass is a lightweight and durable material that offers several advantages over aluminum. Here are some of the benefits of using fiberglass:

- Lightweight: Fiberglass is significantly lighter than aluminum, making it an ideal choice for applications where weight is a crucial factor, such as in the aerospace industry.

- Corrosion-resistant: Unlike aluminum, fiberglass is resistant to corrosion, making it an excellent choice for marine and offshore applications.

- Easy to mold: Fiberglass can be molded into complex shapes, making it a versatile material for various applications.

- Insulating properties: Fiberglass has excellent insulating properties, making it an ideal choice for applications where temperature control is critical.

Disadvantages of Fiberglass

While fiberglass has several advantages, it also has some drawbacks. Here are some of the disadvantages of using fiberglass:

- Limited strength: Fiberglass is not as strong as aluminum, making it unsuitable for applications that require high strength.

- UV degradation: Fiberglass can degrade when exposed to UV radiation, making it unsuitable for outdoor applications.

- Cost: Fiberglass is more expensive than aluminum, making it less cost-effective for some applications.

Advantages of Aluminum

Aluminum is a widely used material that offers several advantages over fiberglass. Here are some of the benefits of using aluminum:

- High strength: Aluminum is stronger than fiberglass, making it an excellent choice for applications that require high strength.

- UV-resistant: Aluminum is resistant to UV radiation, making it suitable for outdoor applications.

- Cost-effective: Aluminum is less expensive than fiberglass, making it a more cost-effective option for some applications.

Disadvantages of Aluminum

While aluminum has several advantages, it also has some drawbacks. Here are some of the disadvantages of using aluminum:

- Heavy: Aluminum is heavier than fiberglass, making it unsuitable for applications where weight is a crucial factor.

- Corrosion: Aluminum is prone to corrosion, making it unsuitable for marine and offshore applications.

- Difficult to mold: Aluminum is difficult to mold into complex shapes, making it less versatile than fiberglass.

In conclusion, both fiberglass and aluminum have their advantages and disadvantages. The choice between the two depends on the specific application and the factors that are most important, such as weight, strength, and cost.

Conclusion

In conclusion, fiberglass and aluminum have their own unique advantages and disadvantages when it comes to weight. Fiberglass is generally lighter than aluminum, but it also has its limitations in terms of strength and durability.

While fiberglass is a popular choice for certain applications, such as boats and aircraft, aluminum is often preferred in industries such as construction and transportation due to its strength and durability.

Ultimately, the choice between fiberglass and aluminum comes down to the specific needs and requirements of the project or application. It is important to carefully consider the pros and cons of each material before making a decision.

Overall, both fiberglass and aluminum have their own strengths and weaknesses, and the choice between the two should be based on the specific needs of the project or application.