Fiberglass is a widely used material in various industries, including construction, automotive, and aerospace. It is known for its durability, strength, and resistance to corrosion. However, there is a common question among people who work with fiberglass: does fiberglass melt?

The answer is not straightforward. Fiberglass is made of glass fibers and a resin matrix, which can have different melting points depending on their composition. Generally, fiberglass does not melt like metal or plastic.

Instead, it undergoes a process called thermal degradation, where the material breaks down and loses its structural integrity when exposed to high temperatures. The temperature at which this occurs varies depending on the type of fiberglass and the specific application it is used for. 23.

Understanding the properties of fiberglass and its behavior under extreme conditions is crucial for ensuring the safety and reliability of products that use this material. In this article, we will explore the topic of whether fiberglass melts and provide insights into the factors that affect its thermal stability.

Understanding Fiberglass

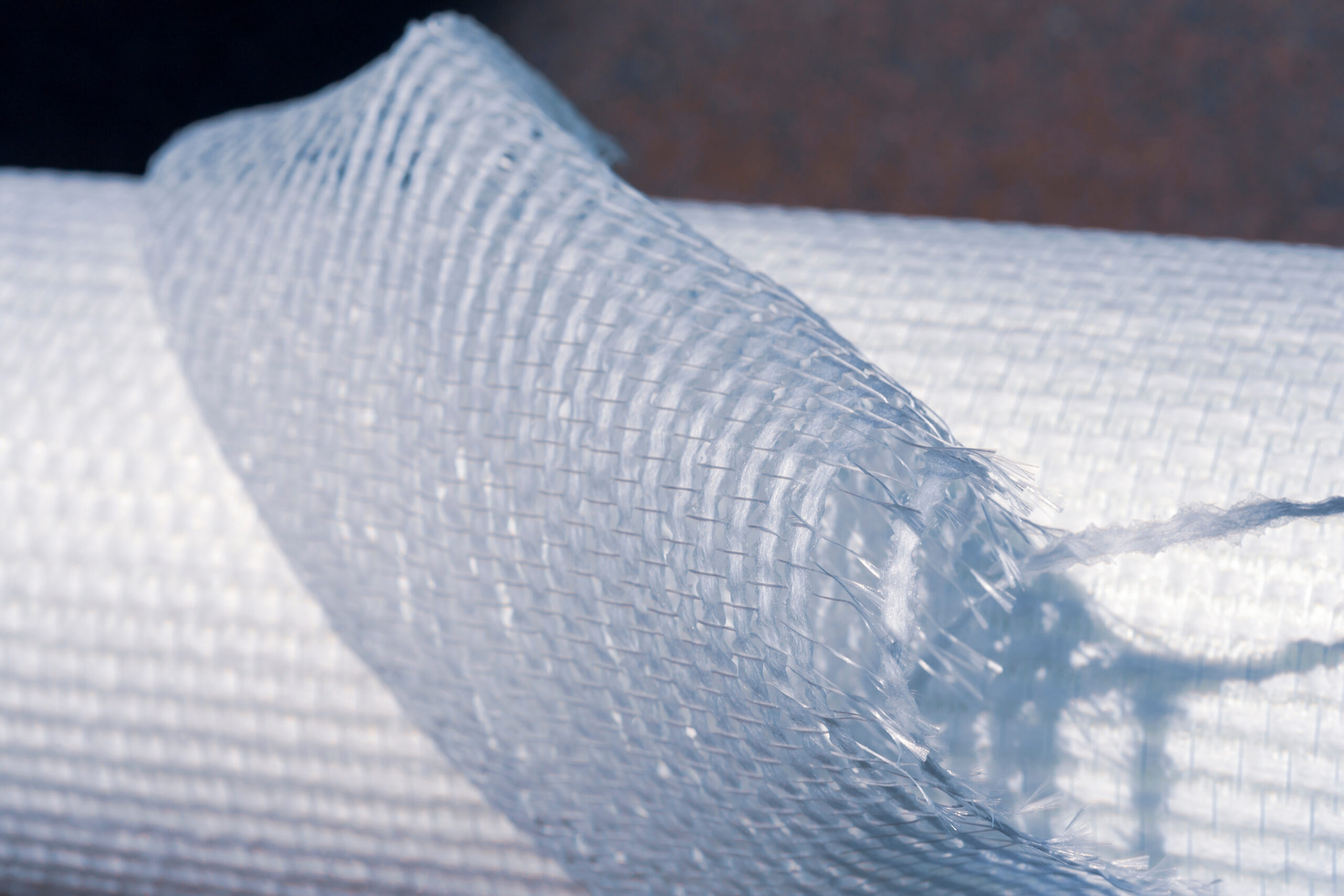

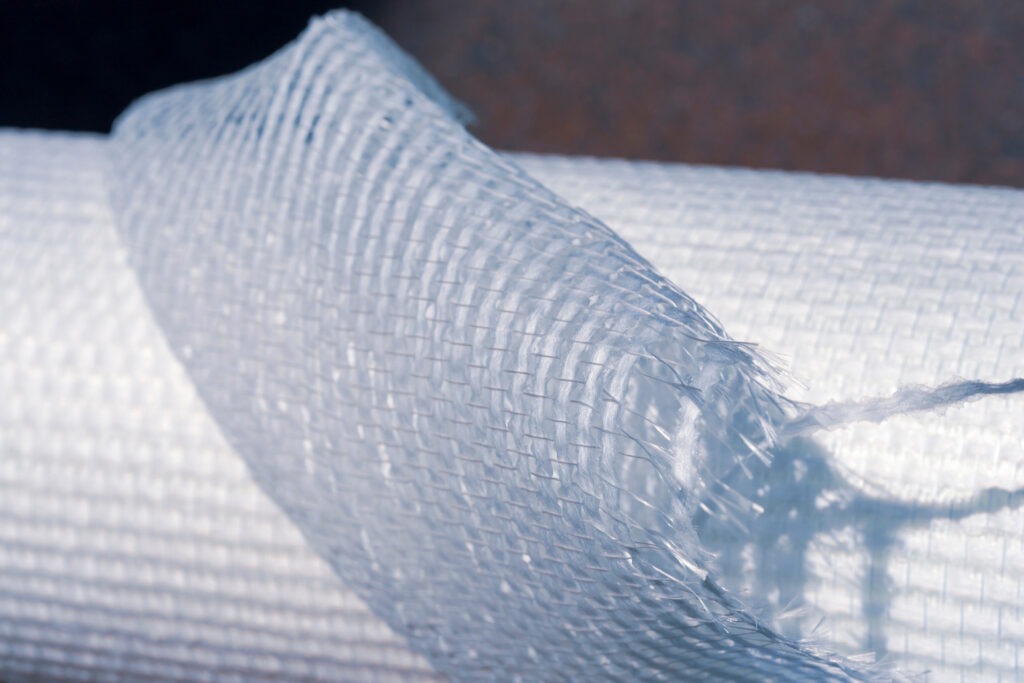

Fiberglass is a composite material made of fine glass fibers woven together with a resin binder. It is widely used in construction, automotive, aerospace, and marine industries due to its strength, durability, and lightweight properties.

The glass fibers used in fiberglass are made from silica, a naturally occurring mineral found in sand. These fibers are then woven together into a fabric-like material that can be molded into various shapes and sizes.

The resin binder used in fiberglass is typically a thermosetting plastic, such as polyester or epoxy. This binder holds the glass fibers together and gives the material its strength and rigidity.

Fiberglass is known for its high melting point, which is typically around 1,200 to 1,500 degrees Fahrenheit. This means that it can withstand high temperatures without melting or degrading.

However, it is important to note that fiberglass can still be damaged by heat, especially if it is exposed to direct flames or prolonged exposure to high temperatures.

Overall, fiberglass is a versatile and durable material that is widely used in various industries. Its high melting point makes it suitable for use in high-temperature applications, but it is important to take proper precautions to prevent damage from heat.

Does Fiberglass Melt?

Fiberglass is a type of composite material that is made up of glass fibers and a plastic resin. It is widely used in various applications such as insulation, boats, cars, and aircraft due to its strength, durability, and lightweight properties.

However, one question that arises in the minds of many people is whether fiberglass melts or not.

The answer to this question is both yes and no. Fiberglass itself does not melt, but the plastic resin used to bind the glass fibers together can melt under high temperatures. The melting point of the resin depends on the type of resin used, but it typically ranges from 200 to 300 degrees Celsius.

When exposed to high temperatures, the resin in fiberglass can soften and lose its structural integrity. This can cause the fiberglass to deform, warp, or even break apart.

Therefore, it is important to use fiberglass in applications where high temperatures are not a concern or to use high-temperature-resistant resins if the application requires it.

In conclusion, fiberglass does not melt, but the plastic resin used to bind the glass fibers together can melt under high temperatures. This should be taken into consideration when using fiberglass in applications where high temperatures are a concern.

Factors Influencing Melting Point

The melting point of fiberglass is affected by several factors. Here are some of the most important ones:

Glass Composition

The type of glass used to make the fiberglass is a crucial factor in determining its melting point. Different types of glass have different chemical compositions, which can affect their thermal properties.

For example, borosilicate glass has a much higher melting point than soda-lime glass. Therefore, fiberglass made from borosilicate glass will have a higher melting point than fiberglass made from soda-lime glass.

Fiber Diameter

The diameter of the fiberglass fibers also affects their melting point. Thinner fibers have a lower melting point than thicker fibers.

This is because thinner fibers have a higher surface area-to-volume ratio, which makes them more susceptible to heat transfer. Therefore, if the diameter of the fiberglass fibers is reduced, their melting point will also decrease.

Additives

Additives can be added to the glass composition to alter its thermal properties. For example, adding alumina to the glass can increase its melting point. However, adding too many additives can also decrease the strength of the fiberglass.

Processing Conditions

The processing conditions used to manufacture the fiberglass can also affect its melting point. For example, if the fiberglass is heated too quickly or too slowly during production, it may affect its thermal properties. The cooling rate after heating can also affect the melting point of the fiberglass.

In summary, the melting point of fiberglass is influenced by various factors such as glass composition, fiber diameter, additives, and processing conditions. Understanding these factors is essential to ensure the proper use and handling of fiberglass materials.

Comparing Fiberglass and Other Materials

Fiberglass is a popular material used in a variety of industries due to its strength, durability, and resistance to corrosion. However, when it comes to high temperatures, many people wonder if fiberglass can melt. To answer this question, it’s important to compare fiberglass to other materials.

Fiberglass vs. Plastic

Plastic is a common material used in many applications, but it has a lower melting point than fiberglass. Most plastics will melt at temperatures between 200-300°C, while fiberglass can withstand temperatures up to 1000°C. This makes fiberglass a better choice for high-temperature applications.

Fiberglass vs. Metal

Compared to metal, fiberglass has a much lower thermal conductivity, which means it doesn’t conduct heat as well. While some metals can withstand high temperatures, they can also become very hot to the touch. Fiberglass, on the other hand, can maintain its shape and strength at high temperatures without becoming dangerously hot.

Fiberglass vs. Ceramic

Ceramic is another material that is known for its high-temperature resistance. While ceramic can withstand temperatures up to 1600°C, it is also brittle and can easily crack under stress. Fiberglass, on the other hand, is much more flexible and can withstand higher temperatures than most ceramics without cracking or breaking.

Overall, fiberglass is a strong and durable material that can withstand high temperatures without melting. When compared to other materials like plastic, metal, and ceramic, fiberglass is often the best choice for applications that require high-temperature resistance.

Implications of Melting Fiberglass

When fiberglass is exposed to high temperatures, it can melt and lose its structural integrity. This can lead to a variety of implications, depending on the context in which the fiberglass is being used.

In construction, melting fiberglass can compromise the strength and safety of a building. For example, if fiberglass insulation in a wall or ceiling melts due to a fire, it can create a gap that allows flames to spread more quickly.

Similarly, if fiberglass-reinforced plastic (FRP) is used in a building’s structure and melts, it can weaken the overall integrity of the building.

In the automotive industry, melting fiberglass can be a safety hazard. Fiberglass is commonly used in car bodies and other components, and if it melts in the event of a fire or high-temperature accident, it can release toxic fumes and compromise the structural integrity of the vehicle.

In industrial settings, melting fiberglass can be a sign of equipment failure or malfunction. For example, if fiberglass insulation in a furnace or boiler melts, it can indicate that the equipment is overheating and needs to be shut down for repairs.

Overall, the implications of melting fiberglass depend on the specific context in which it is being used. However, it is important to be aware of the potential risks and take appropriate precautions to prevent or mitigate the effects of melting fiberglass.

Safety Measures When Handling Fiberglass

When working with fiberglass, it is important to take the necessary safety precautions to avoid any potential hazards. Here are some safety measures that should be followed when handling fiberglass:

Wear Protective Gear

Wearing protective gear is essential when handling fiberglass. This includes wearing gloves, safety goggles, and a face mask to prevent inhaling fiberglass particles. It is also recommended to wear long-sleeved clothing to avoid skin irritation.

Work in a Well-Ventilated Area

Fiberglass produces dust and fumes that can be harmful when inhaled. Therefore, it is important to work in a well-ventilated area to prevent any respiratory issues. If working indoors, ensure that windows and doors are open, and if working outdoors, ensure that there is a breeze.

Use Proper Tools

Using the right tools when handling fiberglass is important to prevent any accidents. Use a saw with a fine-toothed blade to prevent splintering, and use a dust mask when sanding fiberglass. It is also important to use sharp blades to prevent snagging or tearing of the fiberglass.

Clean Up Properly

After working with fiberglass, it is important to clean up properly to prevent any contamination. Use a damp cloth to wipe down surfaces and dispose of any fiberglass scraps in a sealed container. It is also recommended to shower after working with fiberglass to remove any remaining particles.

By following these safety measures, one can safely handle fiberglass without any potential hazards.

Conclusion

In conclusion, fiberglass does not melt in the traditional sense. It can withstand high temperatures without melting, making it a popular choice in industries where heat resistance is important. However, it is important to note that fiberglass can soften and deform under extreme heat, which can lead to structural damage.

Overall, fiberglass is a durable and versatile material that has many applications in various industries. Its ability to withstand high temperatures without melting makes it a popular choice for insulation, electrical components, and other applications where heat resistance is important.

However, it is important to use fiberglass in accordance with manufacturer guidelines to ensure its longevity and safety.